Automotive

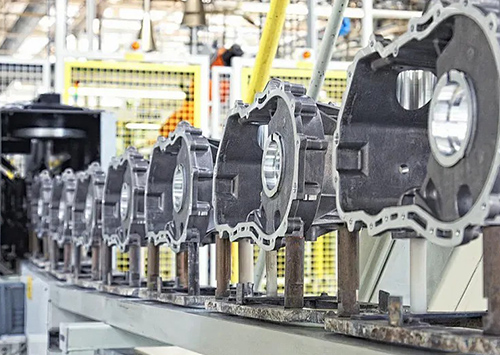

As a metal processing supplier, Xinjiuxinji understands the automotive industry’s demand for high-quality, durable, and precise metal components. Automotive parts must withstand extreme conditions, including temperature changes, mechanical stress, and corrosion, while maintaining lightweight properties for fuel efficiency and performance. Precision and reliability are critical to ensure the safety and longevity of vehicles.

At Xinjiuxinji, we provide custom metal components that meet these stringent requirements. Our ISO 9001:2015 certification guarantees that our products meet top industry standards in quality and performance. With a focus on precision engineering and optimized production, our metal parts ensure durability, strength, and cost-effectiveness, making us a trusted partner for the automotive sector.

Metal processing plays a crucial role in the automotive industry, where precision, durability, and lightweight properties are key. Stamped metal components are used extensively in various automotive parts, ensuring structural integrity and performance.

Metal-Stamped Components

Body Panels

Metal stamping is widely used for manufacturing body panels, which require high durability and impact resistance. These components must be lightweight to enhance fuel efficiency, and their surface finish must support easy painting and corrosion resistance.

Chassis Components

Stamped metal parts in chassis structures must offer strength and rigidity to handle mechanical stress and road conditions. Precision is crucial to maintain the overall integrity and alignment of the vehicle’s frame.

Exhaust Systems

Exhaust systems use metal stamping to create components that can withstand high temperatures and corrosion from gases. These parts need to be heat-resistant and durable while maintaining a lightweight design for performance efficiency.

Suspension Parts

Suspension components, such as control arms and brackets, use stamped metal parts to ensure strength and durability. These parts need to resist fatigue from constant movement and stress while providing smooth and controlled vehicle handling.

Engine Mounts

Stamped metal engine mounts must provide excellent vibration isolation and support, ensuring stability. These components need to be precisely manufactured to fit perfectly and withstand high mechanical loads.

Brake Components

Brake components like calipers and brackets are made using metal stamping for high precision and strength. These parts must endure heat and friction while maintaining a strong, lightweight design to ensure safe braking performance.

Transmission Components

Metal stamping is used in transmission parts, requiring precision and durability to ensure smooth shifting and performance. These components must also be able to withstand mechanical wear and high operating temperatures.

Fuel System Parts

Fuel system components, including tanks and brackets, rely on stamped metal parts for leak resistance and durability. These parts must be corrosion-resistant and precisely made to ensure the safe containment of fuel.

Seat Frames

Stamped metal seat frames must be strong yet lightweight to provide support and comfort. They require precise manufacturing to ensure safety, stability, and compliance with vehicle safety standards, all while keeping overall vehicle weight low.

In the automotive industry, various metals are selected for their unique properties, such as strength, corrosion resistance, and lightweight characteristics. These materials enhance vehicle performance and safety.

Common Metals Used In This Field

Aluminum

Aluminum is prized for its lightweight and corrosion-resistant properties. It is often used in body panels, engine blocks, and wheels, helping reduce overall vehicle weight while maintaining structural integrity, thus improving fuel efficiency and handling.

Steel

Steel is widely used due to its high strength and durability, particularly in chassis and suspension systems. Its ability to withstand mechanical stress and impact enhances vehicle safety, making it essential for key structural components.

Stainless Steel

Stainless steel’s excellent corrosion resistance and heat tolerance make it ideal for exhaust systems and fuel tanks. It provides longevity in harsh environments, ensuring the reliability and durability of critical automotive components.

Magnesium

Magnesium is the lightest structural metal, often used in engine components and gearboxes. Its low density reduces overall vehicle weight, contributing to improved fuel efficiency and performance without sacrificing strength.

Titanium

Titanium is known for its high strength, heat resistance, and lightweight properties, making it ideal for high-performance parts like exhaust systems and engine components. It helps vehicles endure extreme conditions while maximizing efficiency.

Copper

Copper’s superior electrical conductivity makes it essential in automotive wiring and electrical systems. It ensures efficient energy transfer, supporting electronic components and enhancing the overall functionality of the vehicle’s electrical systems.

Nickel

Nickel is used in alloying and plating to enhance corrosion resistance and durability. It protects automotive components like bearings and fasteners from wear and degradation, ensuring longer-lasting performance in demanding environments.

Carbon Steel

Carbon steel is strong and tough, commonly used in gears, fasteners, and other load-bearing components. Its ability to resist wear and withstand heavy mechanical loads makes it vital for maintaining the durability of critical automotive parts.

Zinc

Zinc is primarily used in galvanizing steel to prevent rusting, especially in exposed parts like body panels and undercarriages. Its protective coating increases the longevity of these components by preventing corrosion in harsh conditions.

Your Trusted Partner in Metal Custom: The Xinjiuxinji Advantage

We specialize in customized solutions, optimizing each project to meet specific requirements. Whether it’s adjusting designs for efficiency or tailoring production for unique applications, Xinjiuxinji has the expertise to deliver exceptional results. We’re dedicated to supporting your automotive projects with high-quality, precision-engineered components.

+86 18892239158

+86 18892239158