Electronics

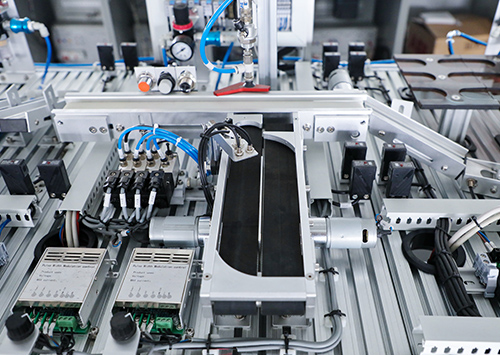

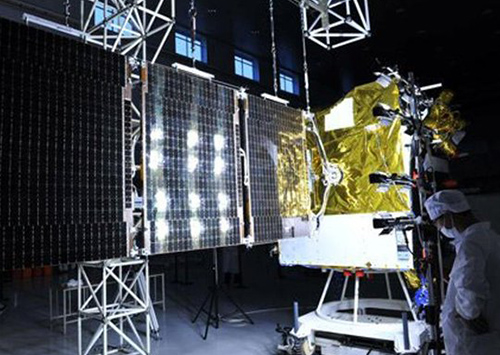

At Xinjiuxinji, we specialize in custom metal parts for the Electronics industry, where precision, conductivity, and durability are paramount. Metal components used in electronics must often meet exacting standards for size, weight, and thermal conductivity while offering protection against corrosion and electrical interference. These parts also require superior accuracy in fabrication to fit seamlessly into intricate electronic systems.

Our company ensures that each metal component we manufacture meets the highest quality standards. Using advanced machining techniques, we deliver parts with exceptional precision, conductivity, and strength. Whether it’s for enclosures, connectors, or heat sinks, Xinjiuxinji guarantees components that enhance performance, reliability, and longevity in electronic devices.

Metal processing plays a critical role in the Electronics industry, providing essential components that ensure device functionality, durability, and performance. Metal stamping is widely used to create precise and reliable parts.

Metal-Stamped Components

Chassis

The chassis provides structural support and housing for electronic devices. Metal stamping ensures precise dimensions and strength, allowing the chassis to protect internal components from damage and vibration.

Connectors

Connectors require high precision and excellent conductivity. Metal stamping allows for intricate shapes and fine details, ensuring secure and efficient connections between electrical circuits.

Heat Sinks

Heat sinks must dissipate heat efficiently to prevent overheating. Stamped metal parts provide excellent thermal conductivity and a large surface area, allowing for optimal heat dissipation in electronic devices.

Shielding Cans

Shielding cans are used to protect sensitive electronic components from electromagnetic interference. Metal stamping provides the precision required to create effective, lightweight shielding with proper grounding.

Brackets

Brackets are used to mount or secure components within electronic devices. These parts must be strong yet lightweight, and metal stamping offers consistent shapes and thickness for reliable assembly.

Battery Contacts

Battery contacts require excellent conductivity and springiness to maintain a constant electrical connection. Stamped metal ensures the precision and material properties needed for long-term performance.

Switch Components

Switches depend on small, precise metal parts to function properly. Metal stamping creates durable, accurate contacts and springs that enable reliable switching action in electronic devices.

Mounting Plates

Mounting plates secure electronic components to other parts of the device. These plates must be strong, lightweight, and precisely made, which is why stamped metal is commonly used for this application.

Enclosures

Enclosures protect electronic circuits from dust, moisture, and mechanical damage. Metal stamping provides custom, high-strength enclosures with precise fitting to safeguard internal components effectively.

Different metals are used in the Electronics industry based on their unique properties, such as conductivity, durability, and corrosion resistance.

Common Metals Used In This Field

Copper

Copper is widely used for its excellent electrical conductivity, making it ideal for wiring, connectors, and printed circuit boards. Its high conductivity ensures efficient power transfer and minimal energy loss.

Aluminum

Aluminum is lightweight and offers good conductivity and heat dissipation, commonly used in heat sinks and casings. Its ability to conduct heat effectively helps prevent electronic components from overheating.

Stainless Steel

Stainless steel is valued for its corrosion resistance and durability. It’s commonly used in enclosures and structural parts, where protection against rust and mechanical wear is critical for long-term device reliability.

Brass

Brass combines good conductivity and resistance to corrosion, making it useful for connectors, terminals, and fittings. Its machinability and strength allow for precise components in small spaces.

Nickel

Nickel is used for its corrosion resistance and ability to create strong alloys. It’s often used in battery components, switches, and shielding, where durability and conductivity are essential for reliable operation.

Gold

Gold is highly conductive and resistant to corrosion, commonly used in high-precision connectors and circuit board plating. Its excellent conductivity ensures reliable connections in critical electronic devices.

Titanium

Titanium is lightweight, strong, and resistant to corrosion, often used in structural components and casings. Its durability ensures long-lasting protection for delicate internal electronic parts.

Zinc

Zinc is often used as a protective coating for other metals, providing excellent corrosion resistance. In electronics, it’s applied in parts that need shielding and protection from environmental factors.

Tin

Tin is used for its excellent solderability and resistance to corrosion, making it ideal for soldering components onto circuit boards. Its low melting point ensures safe and effective bonding in electronic assemblies.

Your Trusted Partner in Metal Custom: The Xinjiuxinji Advantage

At Xinjiuxinji, we are proud to hold the ISO9001:2015 certification, which reflects our commitment to delivering high-quality, precision-manufactured metal components for the Electronics industry. With years of experience, we understand the unique requirements of this sector, particularly the need for accuracy, conductivity, and durability in metal parts. Our production processes are designed to meet the strict standards of the industry, ensuring that every component performs flawlessly in electronic applications.

In addition, Xinjiuxinji excels at providing customized solutions for our clients. We can optimize designs and manufacturing processes to fit your specific project needs, delivering components that improve performance and reliability.

+86 18892239158

+86 18892239158