Metal Hardware

In the Metal Hardware sector, metal components are essential for ensuring durability, strength, and functionality. The requirements for these parts include high precision, resistance to wear and corrosion, and the ability to withstand various environmental conditions. Manufacturers must adhere to strict quality standards to ensure that the hardware can perform reliably over time, particularly in demanding applications such as construction, automotive, and machinery.

At Xinjiuxinji, we specialize in producing custom metal parts tailored to the specific needs of the metal hardware industry. Our rigorous quality control processes, backed by our ISO 9001:2015 certification, ensure that every component meets the highest standards of quality and performance. We leverage advanced machining techniques and materials to deliver precision-engineered solutions that not only satisfy but exceed client expectations. Our commitment to customization allows us to optimize designs and enhance functionality, making us a trusted partner in the metal hardware supply chain.

Metal processing plays a crucial role in the Metal Hardware sector, where metal components are vital for the functionality and reliability of various products. These components must meet specific performance standards, including durability, precision, and resistance to wear and corrosion.

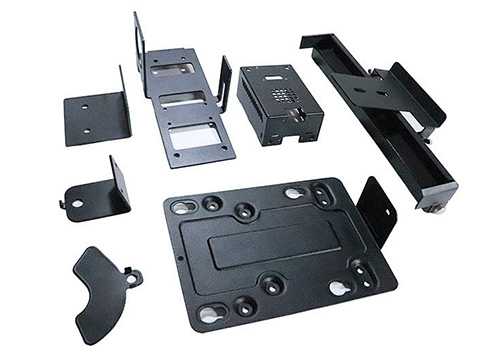

Metal-Stamped Components

Brackets

Brackets must provide robust support and stability. They should be made of high-strength materials to withstand mechanical stress and prevent deformation.

Fasteners

Fasteners like screws and bolts require high tensile strength and precise threading. They must resist loosening under vibration and maintain structural integrity over time.

Hinges

Hinges must ensure smooth operation and durability. They should be corrosion-resistant and designed to bear significant weight without bending or breaking.

Clips

Clips are used to hold components securely in place. They need to have the right tension and flexibility, ensuring they do not break during use.

Covers

Covers must fit snugly and protect internal components. They should be made from materials that resist rust and wear, ensuring longevity and reliability.

Plates

Plates need to provide a solid surface for mounting and should be manufactured to exact dimensions to ensure compatibility with other components.

Spacers

Spacers must be precise in size to maintain proper alignment between parts. They should have a high degree of stability and resistance to environmental factors.

Shims

Shims require high precision to fill gaps and support parts in machinery. They must maintain their shape and resist wear during operation.

Casings

Casings need to be robust to protect internal mechanisms. They should be corrosion-resistant and designed to withstand various environmental conditions.

These components demonstrate the necessity for high-quality metal stamping in the Metal Hardware sector, ensuring that all parts function effectively in their applications.

In the Metal Hardware sector, various metal materials are utilized to manufacture components that offer strength, durability, and resistance to environmental factors. Different metals provide unique characteristics, making them suitable for specific applications.

Common Metals Used In This Field

Steel

Steel is known for its exceptional strength and durability. It is often used in structural components due to its high tensile strength and ability to withstand heavy loads. Steel’s resistance to deformation makes it ideal for applications requiring stability, such as brackets and fasteners.

Aluminum

Aluminum is lightweight and corrosion-resistant, making it suitable for hardware applications where weight is a concern. Its excellent machinability allows for precise fabrication, and it is often used in applications like casings and covers where a balance of strength and weight is essential.

Stainless Steel

Stainless steel offers superior corrosion resistance and strength, making it ideal for components exposed to harsh environments. Its aesthetic appeal also makes it a preferred choice for decorative hardware applications. Stainless steel is often used for hinges and clips.

Brass

Brass is known for its excellent corrosion resistance and low friction properties, making it suitable for applications like fasteners and fittings. Its antimicrobial properties are beneficial in healthcare applications, while its machinability makes it easy to work with for intricate designs.

Copper

Copper has excellent electrical conductivity and corrosion resistance, making it ideal for electrical hardware applications. It is often used in components such as connectors and terminals, where reliable electrical performance is critical.

Titanium

Titanium offers high strength-to-weight ratio and excellent corrosion resistance, making it suitable for high-performance applications. It is commonly used in specialized hardware for aerospace and military applications, where strength and lightness are critical.

Nickel Alloys

Nickel alloys provide excellent resistance to corrosion and high temperatures, making them ideal for demanding environments. They are used in applications where durability and heat resistance are paramount, such as in marine hardware.

Each of these materials plays a crucial role in the Metal Hardware sector, ensuring that components meet the necessary performance standards for durability and reliability.

Xinjiuxinji consistently meet customer expectations for quality and performance. Our expertise allows us to optimize and customize projects according to client specifications, ensuring that every product aligns perfectly with their requirements. Your satisfaction is our priority, and we strive to exceed your expectations.

+86 18892239158

+86 18892239158