Packaging

The Packaging industry demands metal components with a high level of precision, durability, and corrosion resistance to ensure consistent performance in manufacturing and product protection. Metal parts used in packaging machinery must withstand repetitive motion, mechanical stress, and exposure to various environmental factors while maintaining structural integrity.

At Xinjiuxinji, we specialize in producing high-quality custom metal components that meet these stringent requirements. Our expertise in metal stamping and machining ensures precision and reliability, enabling us to deliver parts that excel in strength, wear resistance, and longevity, helping our clients achieve optimal packaging efficiency.

Metal components play a crucial role in the Packaging industry, where they are widely used in machinery for assembly, sealing, and transportation. These metal parts must meet high standards of durability, precision, and corrosion resistance to ensure efficient, long-term operation.

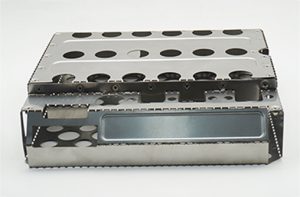

Metal-Stamped Components

Frame Brackets

Frame brackets provide structural support for packaging machines. These components require precise dimensions to ensure the stability and strength of the overall machine frame, which supports heavy loads during operation.

Gears

Gears in packaging equipment must be manufactured with high precision to ensure smooth, consistent rotation and minimal wear. Metal stamping ensures these gears meet high tolerance levels for efficient, long-term use.

Guide Rails

Guide rails direct the movement of packages through assembly lines. They require high wear resistance and smooth surfaces to minimize friction and ensure uninterrupted movement in high-speed operations.

Conveyor Plates

Conveyor plates serve as the base for packaging movement in the machinery. They need to be durable and resistant to corrosion, as they often come in contact with varying products and environmental conditions.

Clamps

Clamps hold materials in place during the packaging process. These parts must be strong and maintain their grip under significant pressure, making durable, stamped metal ideal for their production.

Levers

Levers in packaging machines facilitate manual or mechanical operations. They require precision manufacturing to maintain consistent force and mechanical advantage without risk of deformation under stress.

Sealing Jaws

Sealing jaws apply heat and pressure to close packaging materials. These components must be highly heat-resistant and capable of maintaining shape under repeated heating cycles for proper sealing.

Springs

Springs are essential for controlling movement and tension in packaging systems. Metal stamping allows for the production of highly reliable, flexible springs that withstand continuous compression and tension.

Cutting Blades

Cutting blades slice through packaging materials. They need to be sharp, corrosion-resistant, and strong enough to handle repeated use without losing their cutting edge or shape.

These metal components, manufactured with precise stamping techniques, ensure the functionality and efficiency of packaging equipment.

In the Packaging industry, different metal materials are chosen based on their properties to meet the specific needs of various components. Each metal offers distinct advantages that improve the efficiency, durability, and safety of packaging systems.

Common Metals Used

Stainless Steel

Stainless steel is commonly used due to its corrosion resistance, especially in environments where moisture or chemicals are present. Its strength and hygiene make it ideal for food packaging machinery and conveyor systems.

Aluminum

Aluminum is favored for its lightweight yet strong structure. It is also corrosion-resistant and easy to mold, making it suitable for packaging equipment that requires mobility and flexibility, such as sealing machines.

Brass

Brass is valued for its malleability and resistance to corrosion. It is often used in components requiring intricate shapes, such as bushings and nozzles, due to its machinability and durability.

Copper

Copper’s excellent conductivity makes it essential for electrical components in packaging machinery, such as wiring and connections. It is also antimicrobial, making it suitable for hygienic packaging environments.

Carbon Steel

Carbon steel is chosen for its high tensile strength and durability, often used in components like cutting blades and gears. Its wear resistance helps maintain the efficiency of packaging machines under high-stress conditions.

Titanium

Titanium is extremely strong yet lightweight, ideal for high-performance packaging equipment that requires strength without added weight. Its corrosion resistance also ensures longevity in harsh industrial environments.

Zinc

Zinc is often used for galvanizing components to protect them from rust and corrosion. It is a common material for fasteners and brackets that must endure exposure to moisture.

Nickel Alloys

Nickel alloys provide excellent corrosion resistance and durability in high-temperature environments. They are used in heat-sealing parts of packaging equipment that are exposed to constant temperature changes.

Copper-Nickel

Copper-nickel alloys combine the best of both materials, offering corrosion resistance and strength. These are used in heat exchangers and other systems where both thermal and corrosion resistance are essential.

Your Trusted Partner in Metal Custom: The Xinjiuxinji Advantage

Xinjiuxinji is ISO9001:2015 certified, demonstrating our commitment to maintaining the highest quality standards. With extensive experience in producing precision metal components for the Packaging industry, we ensure that all parts meet strict requirements for accuracy, durability, and performance. Our expertise allows us to optimize and customize solutions tailored to your project needs, guaranteeing that each component we deliver aligns perfectly with your specific applications, enhancing the efficiency and reliability of your packaging systems.

+86 18892239158

+86 18892239158