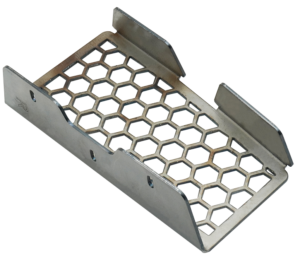

Metal Frame

Detailed Product Description: Frame for Machinery

The metal frame is an essential structural component used in various machinery applications. It providing the necessary support and stability for the machinery’s operation. The product is made from high-strength steel plates, and it undergoes precision manufacturing processes including laser cutting, bending, and laser marking, to ensure both structural integrity and aesthetic finish. The frame is designed to fit specific machinery requirements and withstand operational stress in industrial environments.

Production Technology And Process

-

Material Selection

Material Used:Cold-rolled steel plate is selected for its high strength, durability, and ease of processing. Steel is ideal for producing frames that need to bear significant mechanical loads and perform under various operational conditions.

-

Fabrication Process

Step 1: Laser Cutting

The first step in manufacturing the frame is laser cutting. The steel plate is carefully cut to the exact dimensions required for the frame, including the overall outline and internal cavities or holes that may be necessary for assembly or further mechanical functions.

- Purpose of Laser Cutting:To achieve high precision in shaping the frame’s outline, ensuring the dimensions are accurate and consistent. To create clean, sharp edges without any deformation, which is essential for the fitment and structural integrity of the frame.

- Laser Cutting Precision:The laser cutting machine is programmed with exact coordinates to ensure that each cut is precise and free from defects. The process ensures minimal material waste and maximum accuracy.

- Frame Dimensions:The frame is cut to the specific dimensions of 25 cm × 8 cm × 5 cm to fit the mechanical requirements of the application.

Step 2: Bending

After the laser cutting process, the next step is bending the steel plate.The frame is placed in a hydraulic press brake, where it is bent into the final shape of the frame. The bending process is carried out with a high degree of precision, ensuring that the angles and dimensions are consistent and within tight tolerance limits. A controlled bending process ensures that the steel plate does not undergo any cracking or stress during shaping.

Step 3: Laser Marking

Once the frame has been cut and bent into its final shape, laser marking is used to apply identifying information, such as the company logo, serial numbers, or product specifications. Laser marking ensures that these details are permanent, highly legible, and resistant to wear and corrosion.

-

Assembly and Final Inspection

After all fabrication processes are complete, the frame is carefully assembled and subjected to a final inspection.During this inspection, the dimensions, surface finish, and structural integrity of the frame are checked to ensure it meets the required standards. Any necessary adjustments are made before the frame is ready for delivery or installation.

+86 18892239158

+86 18892239158