Aerospace

As Xinjiuxinji, a metal processing supplier, we understand the aerospace industry demands the highest quality standards for metal components. The aerospace field requires parts with exceptional strength, precision, durability, and resistance to extreme environments. Components must withstand high mechanical stress, temperature variations, and exposure to corrosion while maintaining a lightweight profile to optimize performance in aircraft and spacecraft.

At Xinjiuxinji, we specialize in custom metal part manufacturing, precisely tailored to meet these stringent aerospace requirements. Our advanced machining capabilities ensure that every component is produced with exacting tolerances, meeting the strict dimensional and performance specifications necessary for aerospace applications.

Furthermore, our rigorous quality control processes, including thorough testing and inspection, guarantee that our parts can perform reliably under the extreme conditions typical in aerospace environments. Whether for structural components, engine parts, or specialized hardware, Xinjiuxinji ensures that every metal part we produce is optimized for safety, efficiency, and long-term performance. Our commitment to quality and precision allows us to meet the aerospace industry’s high expectations and deliver components that are critical to the success and safety of aerospace operations.

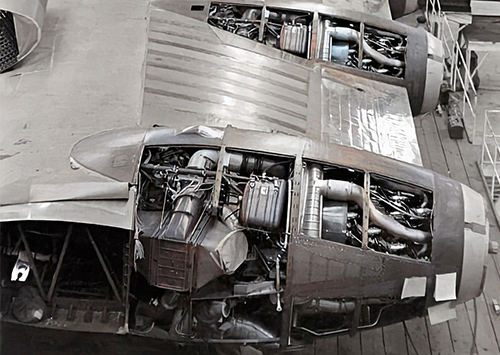

Metal processing, particularly stamping, plays a crucial role in the aerospace industry, enabling the production of lightweight, high-strength components that meet stringent performance requirements.

Metal-Stamped Components

Aircraft Brackets

Metal stamped aircraft brackets provide structural support and require high fatigue resistance to endure vibrations. Custom manufacturing must ensure precise dimensions to prevent stress concentrations.

Engine Mounting Brackets

Engine mounting brackets made from metal stamped parts need to withstand high temperatures and vibrations. Precise stamping is essential to maintain alignment and reduce stress on the engine.

Heat Shields

Metal stamped heat shields must resist extreme heat and protect surrounding components. Manufacturing should focus on material uniformity and surface quality for optimal thermal protection.

Fuel System Clamps

Fuel system clamps need to secure lines and resist corrosion. Stamping must ensure a tight fit to prevent leaks while maintaining the mechanical strength of the clamps.

Landing Gear Struts

Landing gear struts require high strength to absorb impact during landing. Custom manufacturing must ensure the parts are thick and robust to prevent deformation.

Cabin Interior Fittings

Metal stamped fittings in the cabin must be lightweight and fire-resistant. Stamping should ensure smooth edges and consistent dimensions for safety and easy installation.

Electrical Connector Shields

Shields for electrical connectors need to block EMI and fit securely. Manufacturing must focus on tight tolerances and uniform material thickness for effective shielding.

Hydraulic Line Brackets

Hydraulic line brackets must hold high-pressure lines securely. Stamping should guarantee a precise fit and durability to withstand vibration and pressure.

Exhaust System Components

Exhaust system components require high heat and corrosion resistance. Stamping must accommodate thermal expansion and ensure a proper seal to avoid failure.

In the aerospace industry, various metals are used for their unique properties, such as lightweight strength, heat resistance, and durability. These materials are critical for ensuring the safety, efficiency, and longevity of aerospace components.

Common Metals Used In This Field

Aluminum Alloys

Aluminum alloys are lightweight and corrosion-resistant, making them ideal for aircraft structures. Their high strength-to-weight ratio helps improve fuel efficiency and aircraft performance while maintaining structural integrity.

Titanium Alloys

Titanium alloys are known for their exceptional strength and heat resistance. They are commonly used in jet engines and landing gear, where they withstand extreme temperatures and high stress, enhancing durability and performance.

Stainless Steel

Stainless steel offers excellent corrosion resistance and toughness. It is often used in fuel tanks, fasteners, and hydraulic systems, providing durability in harsh environments and ensuring reliable long-term operation.

Nickel Alloys

Nickel alloys, such as Inconel, can maintain their strength at high temperatures, making them perfect for turbine blades and exhaust systems. Their heat resistance is crucial for the efficiency and longevity of engine components.

Magnesium Alloys

Magnesium alloys are extremely lightweight, often used in non-structural components like interior parts. Despite their light weight, they retain good strength, helping reduce overall aircraft mass and improve fuel efficiency.

Copper Alloys

Copper alloys are excellent conductors of electricity and are primarily used in electrical systems and wiring. Their conductivity ensures efficient energy transfer and cooling, crucial for avionics and other critical systems.

Carbon Steel

Carbon steel is used for fasteners and other structural components due to its high tensile strength. It provides the necessary toughness and durability to withstand mechanical stress in various aerospace applications.

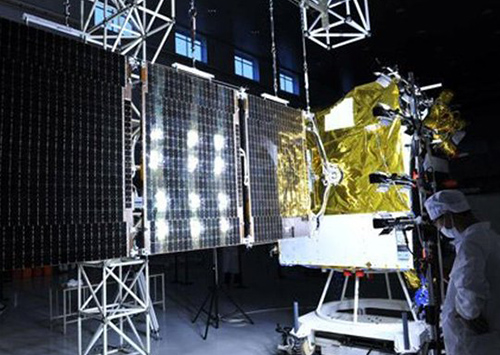

Beryllium Alloys

Beryllium alloys are highly rigid and lightweight, used in satellite components and aerospace instrumentation. Their stability and low weight allow precise control and minimal distortion in space applications.

Cobalt Alloys

Cobalt alloys are used in jet engine parts for their high wear resistance and ability to withstand extreme temperatures. These properties help increase the durability and efficiency of components subjected to high friction and heat.

Your Trusted Partner in Metal Custom: The Xinjiuxinji Advantage

Xinjiuxinji holds the ISO 9001:2015 certification, demonstrating our commitment to high-quality management standards. With extensive experience in the aerospace industry, we excel in delivering metal components that meet the precise accuracy and quality requirements demanded by our clients. Our expertise ensures that all parts we produce adhere to strict tolerances and performance standards, ensuring reliability and safety in aerospace applications.

Moreover, Xinjiuxinji has the capability to optimize and customize solutions according to our clients’ project needs. We collaborate closely with customers to understand their specific requirements and tailor our manufacturing processes to deliver parts that not only meet but exceed expectations. Whether it’s improving the design for enhanced performance or providing material recommendations for optimal results, our team is equipped to offer flexible, customized solutions that align with each unique project in the aerospace sector.

+86 18892239158

+86 18892239158