Services

Nanpi Xinjiu Xinji Hardware Manufacturing Co., LTD., is a global customer to provide full-link metal processing customization company, established in 1999, the company’s main business, sheet metal processing and manufacturing, we are good at stamping, deep drawing, laser cutting, bending, welding, drilling, grinding, spinning, die-casting CNC and other services in various manufacturing fields. Including but not limited to automotive, electronics, medical, home gardening and other fields, to provide the world with relevant metal customization services.

-

Metal stamping is a manufacturing process that uses a press to shape or cut metal into desired forms. This process involves techniques like blanking, punching, bending, and embossing to create par ...

Metal stamping is a manufacturing process that uses a press to shape or cut metal into desired forms. This process involves techniques like blanking, punching, bending, and embossing to create par ... -

Metal laser cutting is a manufacturing process that uses a high-powered laser beam to cut and shape metal materials with extreme precision. The laser melts, burns, or vaporizes the material, creat ...

Metal laser cutting is a manufacturing process that uses a high-powered laser beam to cut and shape metal materials with extreme precision. The laser melts, burns, or vaporizes the material, creat ... -

Metal stretching, also known as metal deep drawning, is a manufacturing process where metal sheets are transformed into complex, three-dimensional shapes by applying tensile force with a die.  Th ...

Metal stretching, also known as metal deep drawning, is a manufacturing process where metal sheets are transformed into complex, three-dimensional shapes by applying tensile force with a die.  Th ... -

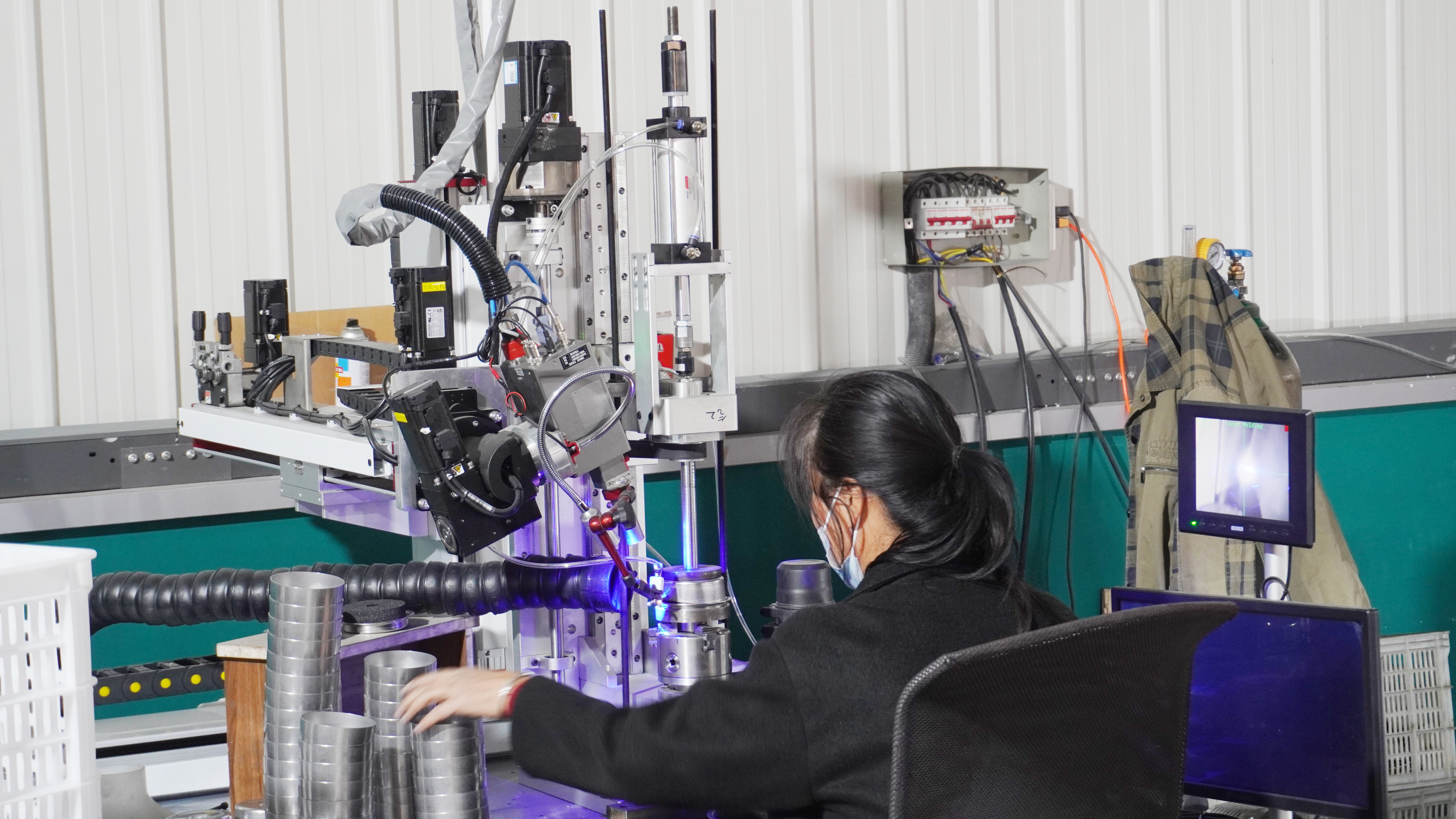

Metal welding is a process of joining metal parts by melting and fusing them, creating a permanent, strong bond. Key types include MIG (Metal Inert Gas) welding, known for speed and versatility; ...

Metal welding is a process of joining metal parts by melting and fusing them, creating a permanent, strong bond. Key types include MIG (Metal Inert Gas) welding, known for speed and versatility; ... -

Metal bending is a precise manufacturing process that reshapes metal sheets into desired forms by applying force, typically with a press brake machine that utilizes a punch and die. The process in ...

Metal bending is a precise manufacturing process that reshapes metal sheets into desired forms by applying force, typically with a press brake machine that utilizes a punch and die. The process in ... -

Metal surface treatment is a process used to improve the surface properties of metal parts, including durability, appearance and corrosion resistance. There are a variety of surface treatment proc ...

Metal surface treatment is a process used to improve the surface properties of metal parts, including durability, appearance and corrosion resistance. There are a variety of surface treatment proc ... -

Metal fabrication is the process of shaping and assembling metal parts to create structures or products. Â There are several types, including cutting, welding, bending, stamping, and machining. Â Me ...

Metal fabrication is the process of shaping and assembling metal parts to create structures or products. Â There are several types, including cutting, welding, bending, stamping, and machining. Â Me ... -

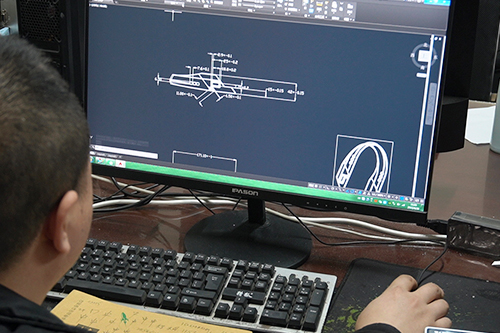

At Xinjiuxinji, our Design & Engineering services cover all aspects of custom metal fabrication, including conceptual design, detailed 3D modeling, material selection, and structural optimizat ...

At Xinjiuxinji, our Design & Engineering services cover all aspects of custom metal fabrication, including conceptual design, detailed 3D modeling, material selection, and structural optimizat ... -

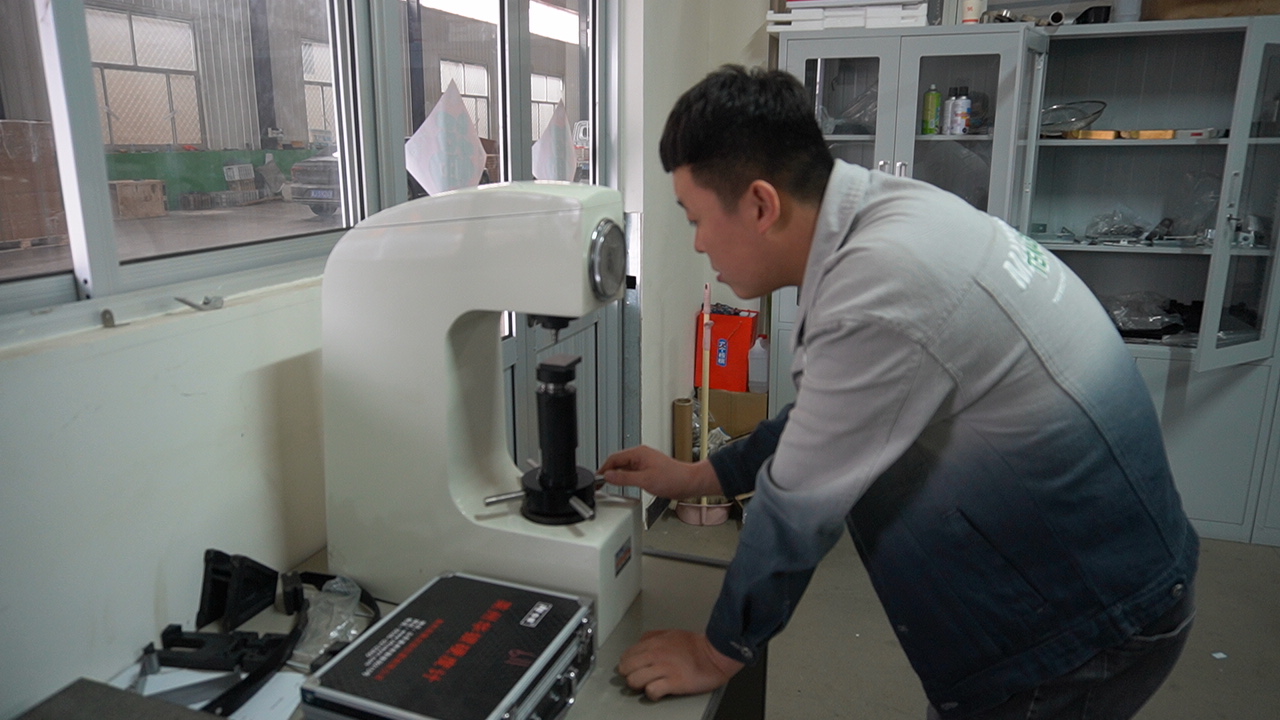

Quality inspection in a metal processing factory is the process of evaluating materials and finished products to ensure they meet specified standards and tolerances. This process involves various ...

Quality inspection in a metal processing factory is the process of evaluating materials and finished products to ensure they meet specified standards and tolerances. This process involves various ... -

In the world of custom sheet metal fabrication, advanced equipment plays a crucial role in producing high-quality, custom metal parts with precision and efficiency. At Xinjiuxinji, we leverage sta ...

In the world of custom sheet metal fabrication, advanced equipment plays a crucial role in producing high-quality, custom metal parts with precision and efficiency. At Xinjiuxinji, we leverage sta ...

1. Metal Stamping

- Progressive Stamping: We offer high-volume progressive stamping, producing intricate parts with minimal waste and precision.

- Deep Draw Stamping: Specializing in deep draw stamping for complex, high-strength components with seamless finishes.

- Single Hit Stamping: Our single hit stamping ensures efficient production of small to medium-sized components with high accuracy.

- Capabilities: Equipped with advanced presses up to 500 tons, we provide custom stamping solutions for diverse industries, ensuring tight tolerances.

2. Laser Cutting Service

- CO2 Laser Cutting: High-speed CO2 laser cutting for thicker metals, delivering clean edges on steel, aluminum, and stainless steel.

- Fiber Laser Cutting: Ideal for thin metals, fiber laser technology offers faster, energy-efficient cutting with superior precision.

- 3D Laser Cutting: 3D laser cutting for complex geometries, enabling versatile design solutions for automotive and aerospace parts.

- Capabilities: With state-of-the-art laser cutting machines, we deliver fast turnaround times for both prototyping and full-scale production.

3. Metal Deep Drawing

- Standard Deep Drawing: Precision deep drawing for cylindrical, conical, and box-shaped parts used in automotive, medical, and electronics industries.

- Multi-Stage Deep Drawing: Complex multi-stage drawing for intricate designs requiring high strength and structural integrity.

- Redrawing Process: We offer redrawing services for parts that need to be drawn multiple times to achieve the desired depth or shape.

- Capabilities: Our high-capacity hydraulic presses enable us to handle deep drawing tasks for various metals, including stainless steel, brass, and aluminum.

4. Welding Service

- MIG Welding: High-quality MIG welding for metals like aluminum, stainless steel, and carbon steel, ensuring durable, precise joints.

- TIG Welding: Precision TIG welding for thin materials, especially stainless steel and aluminum, for highly aesthetic and clean welds.

- Robotic Welding: Automated robotic welding for high-volume projects requiring consistency, speed, and accuracy.

- Capabilities: Our certified welders are experienced in handling both small-scale and large industrial welding projects, ensuring strength and longevity in every weld.

5. Metal Bending

- Press Brake Bending: CNC-controlled press brake bending for custom sheet metal bending with exact angles and dimensions.

- Roll Bending: Roll bending services for curved or cylindrical metal components, ensuring smooth and consistent curves.

- V-Bending: Precision V-bending for angular metal parts used in construction, automotive, and appliance industries.

- Capabilities: With cutting-edge bending equipment, we can achieve complex bends on a variety of metals, ensuring structural integrity and aesthetic precision.

6. Surface Treatment

- Powder Coating: Durable powder coating solutions offering corrosion resistance, with a wide range of colors and finishes available.

- Anodizing: Anodizing services for aluminum components, enhancing corrosion resistance and improving the surface hardness.

- Electroplating: Metal electroplating services to enhance conductivity and corrosion resistance, commonly used in automotive and electronics.

- Capabilities: Our advanced surface treatment processes ensure enhanced durability and performance, tailored to meet specific industrial requirements.

7. Metal Fabrication

- Sheet Metal Fabrication: Comprehensive sheet metal fabrication services, including cutting, forming, and assembly for custom projects.

- Heavy Metal Fabrication: Specialized in heavy-duty metal fabrication for large structures used in construction, mining, and transportation.

- Tube Fabrication: Custom tube fabrication services for metal tubing, including bending, forming, and welding.

- Capabilities: Our full-service metal fabrication shop is equipped with modern CNC machines, enabling us to handle projects from design to final production.

8. Design & Engineering

- CAD Design: We offer professional CAD design services for precise and innovative product development, tailored to customer specifications.

- Prototyping: Rapid prototyping services to bring your designs to life quickly, ensuring feasibility before full-scale production.

- Reverse Engineering: Reverse engineering solutions to recreate existing components with improved functionality or new materials.

- Capabilities: Our in-house engineering team works closely with clients to develop efficient, cost-effective designs, leveraging advanced software and simulation tools.

9. Quality Inspection

- CMM Inspection: Coordinate Measuring Machine (CMM) inspection for high-precision part verification, ensuring exact specifications are met.

- Non-Destructive Testing (NDT): NDT services such as ultrasonic, radiographic, and magnetic particle testing to ensure material integrity without damaging components.

- Dimensional Inspection: Comprehensive dimensional inspection using advanced measuring instruments to guarantee adherence to tolerances.

- Capabilities: Our dedicated quality control team ensures every part undergoes rigorous testing and inspection, adhering to ISO and other international standards to deliver high-quality products.

+86 18892239158

+86 18892239158