Farming Equipment

In the Farming Equipment sector, metal components must be highly durable and resistant to wear, as they are subject to rigorous operational conditions and environmental stresses. These parts often face exposure to moisture, chemicals, and heavy loads, necessitating materials that offer exceptional strength, corrosion resistance, and fatigue durability.

At Xinjiuxinji, we specialize in producing custom metal parts tailored for the Farming Equipment industry. Our ISO 9001:2015 certification ensures that we adhere to stringent quality control processes, guaranteeing that our components meet the highest standards for precision and reliability. By utilizing advanced manufacturing techniques and high-quality materials, we deliver products that enhance the performance and lifespan of farming equipment, providing our clients with dependable solutions for their agricultural needs.

Metalworking plays a vital role in the Farming Equipment sector, where precision-engineered metal components are essential for the durability and efficiency of machinery. These components must withstand harsh operating conditions, making the selection of appropriate materials and manufacturing processes crucial for performance and longevity.

Metal-Stamped Components

Chassis Components

Chassis components must provide structural integrity and support for the entire machine. They require high tensile strength to handle loads and are often made from high-strength steel to resist bending and deformation.

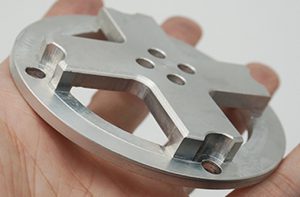

Hitch Plates

Hitch plates are used for connecting implements to tractors and need to withstand significant stress and impact forces. These components must be manufactured with durable materials and precise tolerances to ensure reliable performance during operation.

Brackets

Brackets are essential for mounting various parts and need to be robust yet lightweight. They must be designed to prevent flexing under load, requiring careful selection of materials to balance strength and weight.

Gear Housings

Gear housings protect internal mechanisms and must be made from corrosion-resistant materials. They require precise machining to ensure proper alignment and function of the gears, contributing to overall operational efficiency.

Pulleys

Pulleys facilitate the movement of belts and chains in farming machinery. They need to be durable and resist wear over time, often requiring a hardening process to improve their performance under load.

Frames

Frames provide the foundational structure for farming equipment. They must be fabricated from high-strength metals to endure harsh environmental conditions while maintaining stability and functionality.

Tines

Tines are used in various implements for tilling and cultivating soil. They must be tough and resistant to bending, with sharp edges that remain effective over time, necessitating the use of hard-wearing metals.

Roller Assemblies

Roller assemblies are critical in equipment for seed planting and tillage. They require high-quality metal for durability and must be designed to reduce friction, ensuring smooth operation during extensive use.

These components highlight the importance of metalworking in farming equipment, emphasizing durability, precision, and performance. Properly designed and manufactured stamped metal parts are essential for ensuring the efficiency and reliability of agricultural machinery.

In the Farming Equipment sector, various metal materials are crucial for manufacturing components that ensure durability and performance in harsh environments. Each metal’s unique properties cater to specific needs in agricultural machinery, enhancing efficiency and reliability.

Common Metals Used In This Field

High-Strength Steel

High-strength steel is widely used for structural components due to its exceptional tensile strength and resistance to deformation. This material ensures that farming equipment can withstand heavy loads and harsh working conditions, thereby increasing the durability and lifespan of machinery.

Stainless Steel

Stainless steel is favored for components exposed to moisture and corrosive environments, such as those in farming equipment. Its excellent corrosion resistance and low maintenance requirements make it ideal for parts like hitches and frames, ensuring longevity and performance over time.

Aluminum Alloys

Aluminum alloys are used for components that require a lightweight yet strong material. Their high strength-to-weight ratio makes them ideal for frames and brackets, reducing the overall weight of equipment while maintaining structural integrity, which improves fuel efficiency.

Cast Iron

Cast iron is often used for heavy-duty components such as gear housings and engine blocks. Its excellent wear resistance and ability to absorb vibrations contribute to the durability of farming machinery, allowing for smooth operation under heavy loads.

Bronze

Bronze is used for wear-resistant components such as bushings and bearings in farming equipment. Its self-lubricating properties reduce friction and wear, increasing the lifespan of moving parts and enhancing overall equipment reliability.

Carbon Steel

Carbon steel is known for its toughness and ability to withstand impact, making it suitable for components like tines and plows. Its hardness and strength are crucial for ensuring that these parts can endure the rigors of soil penetration and tillage.

Galvanized Steel

Galvanized steel is coated with zinc to prevent rust and corrosion, making it ideal for outdoor equipment. This material is often used in various components exposed to the elements, ensuring long-lasting performance and reducing the need for frequent maintenance.

Each of these materials plays a pivotal role in enhancing the performance, durability, and efficiency of farming equipment, ensuring that agricultural operations can be conducted effectively in varying conditions.

Your Trusted Partner in Metal Custom: The Xinjiuxinji Advantage

Xinjiuxinji is ISO 9001:2015 certified and brings extensive experience in manufacturing metal components for the Farming Equipment sector. Our commitment to precision and quality ensures that we meet our clients’ stringent product requirements. We take pride in our ability to optimize and customize projects according to customer specifications, enhancing both functionality and performance. Partner with us for reliable, high-quality solutions tailored to your needs.

+86 18892239158

+86 18892239158