Fire Fighting Equipment

In the fire fighting equipment sector, metal components must meet stringent requirements regarding durability, corrosion resistance, and thermal stability. These components, such as hoses, valves, and fittings, are subjected to extreme conditions, including high temperatures and pressures. Therefore, precision engineering and the selection of high-performance materials are crucial to ensure reliability and safety.

At Xinjiuxinji, we specialize in custom-manufactured metal parts that adhere to these critical standards. Our ISO9001:2015 certification underscores our commitment to quality and precision. We utilize advanced manufacturing techniques and rigorous quality control measures to produce components that not only meet but exceed industry expectations. Our team is dedicated to optimizing designs and customizing solutions to address the specific needs of firefighting equipment, ensuring that our products provide dependable performance in life-saving situations.

In the firefighting equipment sector, metal components play a critical role in ensuring the reliability and effectiveness of firefighting operations. These components must be designed to withstand extreme conditions, including high pressures and temperatures, while maintaining structural integrity.

Metal-Stamped Components

Fire Hose Fittings

Fire hose fittings require high durability and resistance to corrosion. These stamped metal parts must ensure a secure connection under high pressure to prevent leaks during use.

Valves

Valves in firefighting equipment must be precise to control water flow effectively. The stamped components need to be resistant to wear and capable of withstanding high temperatures.

Nozzles

Firefighting nozzles must provide adjustable spray patterns. Stamped metal parts must be lightweight yet robust, ensuring reliability under extreme conditions.

Mounting Brackets

Mounting brackets support various firefighting equipment. These components require excellent strength and durability, ensuring they can bear significant weight without deformation.

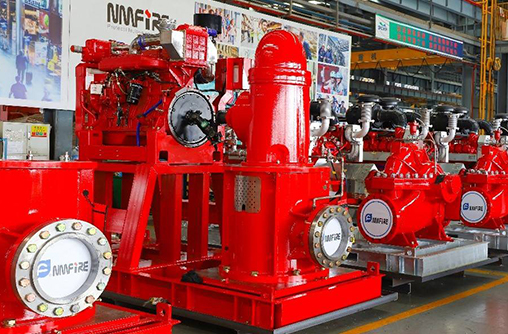

Pump Casings

Pump casings must be impermeable and capable of handling high pressure. Stamped metal casings require precise dimensions and material strength to ensure efficient pump operation.

Connectors

Connectors in firefighting equipment need to maintain a secure connection. The metal stamping process must ensure tight tolerances and resilience against corrosion for long-term reliability.

Hose Reels

Hose reels must operate smoothly while holding hoses securely. The stamped components require high tensile strength and corrosion resistance to ensure functionality in adverse conditions.

Ladders

Metal components in firefighting ladders must provide high structural integrity and stability. They should be lightweight for portability yet strong enough to support significant weight.

Fire Extinguishers

Fire extinguishers require stamped metal parts that are pressure-tested for safety. Components must be reliable under high pressure and resistant to rust for long-lasting performance.

In summary, metal stamping components are crucial in manufacturing firefighting equipment, as they provide the necessary strength, precision, and durability required in demanding environments.

In the firefighting equipment industry, various metals are utilized to manufacture components that ensure safety and performance. Each metal’s unique properties are critical in providing the strength and durability needed to withstand extreme conditions.

Common Metals Used In This Field

Stainless Steel

Stainless steel is renowned for its exceptional corrosion resistance and durability. Its ability to maintain structural integrity under high temperatures makes it ideal for components like valves and nozzles in firefighting equipment. Additionally, it is easy to clean and maintain, ensuring longevity in harsh environments.

Aluminum

Aluminum is lightweight yet strong, making it perfect for portable firefighting tools such as ladders and hose reels. Its natural corrosion resistance helps reduce maintenance needs, while its high strength-to-weight ratio improves maneuverability during emergencies.

Carbon Steel

Carbon steel offers high tensile strength and hardness, making it suitable for critical components such as pump casings and connectors. Its toughness allows it to withstand high pressure and impact, ensuring reliability under extreme operational conditions.

Brass

Brass provides excellent machinability and resistance to corrosion, making it a preferred material for fittings and connectors in firefighting equipment. Its ability to resist wear and tear ensures the longevity of components that are frequently connected and disconnected.

Copper

Copper is often used in fire alarms and electronic components due to its excellent electrical conductivity. Its antimicrobial properties are beneficial in ensuring hygiene, especially in equipment that may come into contact with various contaminants.

Bronze

Bronze combines strength and corrosion resistance, making it ideal for marine firefighting equipment. Its low friction properties enhance the performance of moving parts, such as valves and gears, in high-stress environments.

Nickel Alloys

Nickel alloys are used for components that require high resistance to heat and oxidation, such as in high-pressure hoses and fire extinguishers. Their durability ensures safety during firefighting operations, even in extreme heat conditions.

Zinc Alloys

Zinc alloys are primarily used for coatings and protective finishes on metal components. They provide excellent corrosion resistance and help prolong the lifespan of firefighting equipment, especially in harsh environmental conditions.

These materials ensure that the firefighting equipment performs reliably under intense conditions, ultimately contributing to the safety and effectiveness of firefighting operations.

Your Trusted Partner in Metal Custom: The Xinjiuxinji Advantage

Xinjiuxinji is proud to hold the ISO 9001:2015 certification, demonstrating our commitment to quality management in the production of metal components for the firefighting equipment sector. Our extensive experience allows us to meet stringent accuracy and quality standards, ensuring that our products fulfill customer specifications. Additionally, we offer optimization and customization capabilities tailored to individual project requirements, enhancing performance and reliability in critical applications.

+86 18892239158

+86 18892239158