Laser Cutting Service

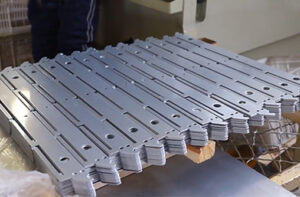

Metal laser cutting service is a manufacturing process that uses a high-powered laser beam to cut and shape metal materials with extreme precision. The laser melts, burns, or vaporizes the material, creating clean and accurate cuts.Xinjiuxinji provide one-stop laser cutting service.

High-Precision Laser Cutting Service | Guaranteed Efficiency And Quality

Xinjiuxinji as a professional Laser cutting service supplier, we focus on providing high-precision and high-efficiency laser cutting services to customers in various industries. Relying on two high-performance laser cutting machines, 5kW and 6kW respectively, we have achieved full coverage from thin plate precision processing to thick plate efficient cutting.

Dual Machine Collaboration, Flexible Response To Complex Needs

5kW fiber laser cutting machine: specially designed for precision thin plate processing, suitable for stainless steel (0.5-12mm), aluminum alloy (0.5-10mm) and other materials, with a cutting accuracy of ±0.05mm, meeting the needs of high-precision parts such as electronic components and medical devices.

6kW high-power laser cutting machine: can efficiently process medium and thick plates (carbon steel ≤25mm, stainless steel ≤18mm), with a 30% increase in cutting speed, suitable for mass production of engineering machinery, automotive structural parts, etc.

Intelligent Process Control

Equipped with top-level cutting head and automatic focusing system, it optimizes the focus position in real time to ensure that the cutting section of materials of different thicknesses is smooth and burr-free. It is also equipped with AI nesting software to maximize the utilization of plates ,In this way, Xinjiuxinji can help customers save costs in laser cutting service.

Professional Laser Cutting Service Factory: Advantages And Services

- Flexible Project Size: We handle both small, detailed parts and large-scale production with equal efficiency, whether it’s a single prototype or a mass production order.

- Cost Efficiency: Our cutting process reduces material waste, making it cost-effective for both small and large projects.

- Precision Cutting: Our laser technology provides high accuracy and clean cuts, even for complex shapes and fine details. We ensure tight tolerances and minimal material deformation.

- Consistency: Each part produced is consistent in quality, from the first to the last, ensuring reliable results for your project.

- Material Versatility: We work with a wide range of metals, including stainless steel, aluminum, and carbon steel laser cutting service providing flexibility in material selection.

>> Learn More About The Materials Commonly Used for Metal Laser Cutting Service

With our expertise and cutting-edge technology, we guarantee high-quality results and a seamless experience for all your metal laser cutting service needs.

Metal Laser Cut Parts: Wide Range Of Applications

1. Automotive Industry

- Requirements: High precision, mass production capability, and the ability to handle complex shapes for lightweight, durable components.

- Laser-Cut Components:

- Exhaust systems

- Chassis parts

- Brackets

- Heat shields

- Body panels

2. Aerospace Industry

- Requirements: Lightweight but strong materials like aluminum and titanium, precise cuts, and strict adherence to safety and regulatory standards.

- Laser-Cut Components:

- Aircraft panels

- Turbine blades

- Structural brackets

- Precision enclosures

3. Electronics Industry

- Requirements: High precision for small and intricate parts, clean edges, and materials with good conductivity or heat resistance.

- Laser-Cut Components:

- Enclosures for electronic devices

- Heat sinks

- Circuit board frames

- Connectors

4. Medical/Healthcare Industry

- Requirements: Use of biocompatible materials like stainless steel and titanium, precision cutting, and ensuring sterility through smooth finishes.

- Laser-Cut Components:

- Surgical instruments

- Implants

- Medical device enclosures

5. Energy Sector

- Requirements: Durability, corrosion resistance, and ability to withstand environmental stresses while providing high-efficiency solutions.

- Laser-Cut Components:

- Solar panel frames

- Wind turbine components

- Battery housings

- Heat exchangers

6. Industrial Equipment

- Requirements: High durability and precision, often for thick materials, ensuring robust components for heavy-duty use.

- Laser-Cut Components:

- Machine frames

- Custom brackets

- Control panels

- Equipment housings

Laser cutting is an advanced manufacturing process that uses a focused laser beam to cut, shape, or engrave various types of metal with extreme precision.High Precision,Versatility,Speed and Efficiency,Clean Edges,Minimal Material Distortion

Ready to Get Started? Contact Xinjiuxinji for Your Metal Custom Needs

If you’re interested in learning more about how laser cutting can benefit your project, feel free to contact us for personalized advice and explore how we can meet your specific needs.We’re here to help with expert guidance on all aspects of laser cutting service.

+86 18892239158

+86 18892239158