Metal Stamping

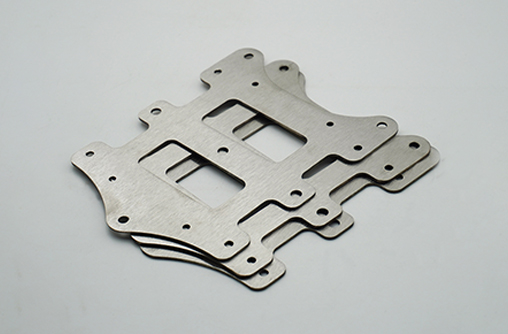

Metal stamping is a manufacturing process that uses a press to shape or cut metal into desired forms. This process involves techniques like blanking, punching, bending, and embossing to create parts from metal sheets.The advantages of metal stamping include high precision, cost efficiency in large production runs, fast production speed, and the ability to produce complex shapes with consistent quality.

Custom Metal Stamping Service:One-Stop metal stamping part manufacturer

Xinjiuxinji is a company specializing in providing customized metal stamping services. We have a team of 16 professional engineers and advanced 60-400ton stamping machines. While helping you complete product prototype design, we can also help you optimize your project from a professional perspective. With more than 20 years of experience in exporting metal stamping parts, we continuously optimize our services so that you can quickly get low-cost and high-quality products.

High-Quality Custom Metal Stamping Solutions From XinjiuXinji

-Custom Metal Stamping: High-precision stamping for parts tailored to client specifications.

-Prototyping: Rapid prototyping services to ensure design feasibility before mass production.

-Design & Engineering Assistance: Expert consultation to optimize product designs for cost-effective and efficient manufacturing.

-Tooling & Die Development: In-house development of custom tooling and dies for precise and repeatable production.

-Assembly Services: Integration of stamped parts into assembled components if required.

-Secondary Processing: Offering additional processes such as welding, drilling, tapping, and machining.

-Surface Finishing: Options for plating, painting, polishing, and other finishing treatments.

-Quality Control: Comprehensive inspection and testing to ensure each part meets stringent quality standards.

-Packaging & Shipping: Customized packaging solutions and efficient logistics to deliver products safely and on time.

>>Learn More About The Factory Equipment

On this basis, XinjiuXinji helps you complete the prototype design, whether you are a small batch or a large project, our company’s professional and mature technical team can provide you with the lowest cost project plan, high-quality product output, from design, processing, assembly to packaging, to provide one-stop sheet metal processing services

Stainless Steel/Aluminum Alloy Stamping Processing

Stainless steel metal stamping and aluminum stamping are more common in metal stamping. Each product has different application requirements and different material choices. The same material also has different choices. For example, there are dozens of types of stainless steel. With our many years of customization experience, we can easily choose the most suitable material for customers.

For example Stainless Steel

Material Properties:

– Corrosion-resistant, durable, aesthetic finish.

– Ideal for medical devices, food processing, and marine applications.

Common Grades

– AISI 304: Most versatile, excellent corrosion resistance.

– AISI 316: Superior corrosion resistance (marine/chemical environments).

– AISI 430: Magnetic, cost-effective for appliances and trim.

– AISI 301: High work-hardening rate for springs/clips.

>> Learn More About The Materials Commonly Used for Metal Stamping

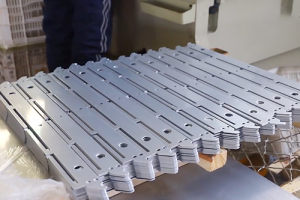

Metal Stamping Capabilities: Small To Large Parts

Metal parts come in different sizes and shapes. However, we have been able to customize and process more than 70,000 different metal parts. The most important of these is our stamping machines. We have the largest single-point 400-ton stamping machine. We use the most advanced hydraulic machines and can also match the one-piece molding mold for efficient mass production. Our professional metal processing project engineers support our customization capabilities. Engineers can provide the best solution for the size, shape and application performance of each metal customization project.

Metal Stamping Process:Wide Range Of Applications

1. Aerospace:

- Fabrication requires lightweight and high-strength materials like aluminum or titanium alloys. Precision is critical, with tight tolerances to meet aerospace safety standards. Corrosion resistance and ability to withstand extreme temperatures are also essential.Common metal stamped components that Xinxjiuxinji creates for the Aerospace include:

- Fuselage panels, engine components, brackets

2. Automotive:

- High-volume production requires repeatability and consistency. Materials like steel and aluminum are commonly used, with focus on corrosion resistance, formability, and lightweight for fuel efficiency. Parts need to be strong and durable, often requiring surface coatings for protection.Common metal stamped components that Xinxjiuxinji creates for the Automotive include:

- Body panels, door frames, hoods, roofs, underbody shields, exhaust system heat shields.

3. Construction Tools:

- High durability and toughness are critical, as parts must withstand impact, stress, and wear. Metals like steel are used for their strength, with surface treatments to prevent rust. Precision bending and forming are essential for strength in structural components.Common metal stamped components that Xinxjiuxinji creates for the Construction Tools include:

- Toolboxes, frames for machinery, hand tool casings, scaffolding platforms.

4. Electronics:

- High precision required for small, intricate parts. Metals like aluminum, stainless steel, and copper are commonly used for their electrical conductivity and thermal properties. Parts need to be lightweight, with clean edges and accurate holes for electronic components.Common metal stamped components that Xinxjiuxinji creates for the Electronics include:

- Enclosures, chassis, brackets for circuit boards, heat sinks, battery housings.

5. Energy:

- Parts must be designed for corrosion resistance and durability under extreme environmental conditions. The focus is on material strength, often using stainless steel or coated metals. Components need to be lightweight but able to handle stress and fatigue over time.Common metal stamped components that Xinxjiuxinji creates for the Energy include:

- Solar panel frames, wind turbine casings, battery housings, heat exchangers.

6. Metal Hardware:

- Focus on strength, aesthetics, and surface finishes like plating or powder coating for consumer-facing products. Metals must be strong enough for load-bearing applications but also lightweight when required. Precision is essential for functionality and fit.Common metal stamped components that Xinxjiuxinji creates for the Metal Hardware include:

- Hinges, brackets, cabinet hardware, handles, locks.

>> Learn More About The Metal Stamping Service Application Areas

Metal Stamping Suppliers?Contact Xinjiuxinji For Your Metal Custom Needs

As an experienced metal stamping factory, we provide the best cost and high quality metal processing services to the world. Our professional staff and advanced equipment enable us to continue to move towards the world.

+86 18892239158

+86 18892239158