Metal Deep Drawning

Metal stretching, also known as metal deep drawning, is a manufacturing process where metal sheets are transformed into complex, three-dimensional shapes by applying tensile force with a die. This technique is essential in industries needing high-precision metal components, such as sinks, baking pans, plumbing fixtures, automotive parts, beverage cans, and casings.

XinjiuXinji Hardware manufacturing Co., LTD is a specialized provider of custom metal stretching services, equipped to handle projects of varying sizes with ease and precision. Our factory is designed to meet high production demands, ensuring scalability from small batch prototypes to large-scale manufacturing runs. We pride ourselves on delivering exceptional quality and precision, maintaining strict tolerances to meet the most exacting specifications. With advanced machinery and a skilled team, Xinjiuxinji guarantees durability, consistency, and efficiency, making us a trusted partner for high-precision metal components across industries.

Material: Aluminum Thickness: 0.8mm

- After four stretches, the outline is drawn.

- Extrude the texture through the beading process.

- After punching, flanging, trimming and further forming.

- The spinning process pulls out the thread.

- Surface treatment oxidized black.

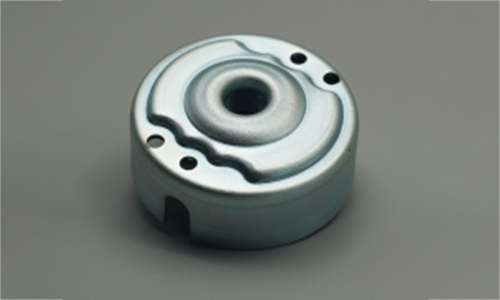

Material: Steel thickness :1.1mm

- After 1 stretch, a finished shape.

- By punching, stamping, further forming.

- Surface treatment galvanized.

Material: Stainless steel thickness :0.6mm

- After 1 stretch, a finished shape.

- Trim edges to further shape.

- Surface treatment polishing.

- Cover with protective film.

Metal Drawing Projects Usually Include Several Key Stages

- Design and Planning

This initial phase involves collaborating closely with the client to define the part’s specifications, including dimensions, tolerances, material type, and any special requirements. A detailed CAD model is created, often including simulations to test feasibility and performance.

- Material Selection and Preparation

Based on the design, we select the appropriate metal (e.g., stainless steel, aluminum, copper). The material is then prepared by cutting it to size and ensuring it is free of contaminants, as cleanliness is essential for quality stretching.

- Tooling and Die Preparation

Custom tooling and dies are created or adjusted to match the part’s design. Properly prepared tooling is essential for achieving accurate shapes and maintaining consistency across production runs.

- Stretching Process

The stretching process begins with placing the prepared material in the die and applying controlled pressure. Through deep drawing or other stretching techniques, the material is gradually shaped into the desired form, carefully monitoring for stress, strain, and alignment.

- Trimming and Shaping

After stretching, excess material is trimmed, and the part is further shaped to meet exact specifications. This step may involve additional processes like bending or fine-tuning details.

- Surface Finishing

Depending on the part’s intended application, surface treatments like polishing, anodizing, or coating may be applied. These finishing touches enhance corrosion resistance, durability, and visual appeal.

- Quality Inspection and Testing

Each part undergoes rigorous inspection to verify it meets the client’s specifications. Tests may include dimensional checks, structural integrity evaluations, and, if required, specialized testing for industry standards.

These steps form the essential workflow for producing high-quality stretched metal components, ensuring each piece meets the exact needs of the client.

metal stretching enables the creation of parts with seamless finishes, high structural integrity, and excellent strength-to-weight ratios. Seamless designs provide increased durability and strength without the need for secondary joining processes.

Ready to Get Started? Contact Xinjiuxinji for Your Metal Custom Needs

If you’d like to learn more about how metal stretching can elevate the quality and performance of your products, feel free to reach out to us. Our team is ready to provide insights into how this technique can be tailored to meet your unique needs and help you achieve optimal results. Contact us today for more details!

+86 18892239158

+86 18892239158